Machine à panneau sandwich EPS

Informations de base

Modèle: as the client request

Description du produit

1. épaisseur: 0.4mm-0.6mm

2. Largeur de rouleau 1200 mm.

3. Puissance: 235MPa.

4.material: EPS et ro

NOUS POUVONS CONÇU LA MACHINE DE PANNEAU DE SANDWICH EPS SELON VOTRE PROFIL OU ECHANTILLON.

Machine à panneau sandwich EPS

Description du produit

1. Paramètres techniques

Sandwich panel specification | ||

1 |

length |

cutting length≥2 m |

2 |

width |

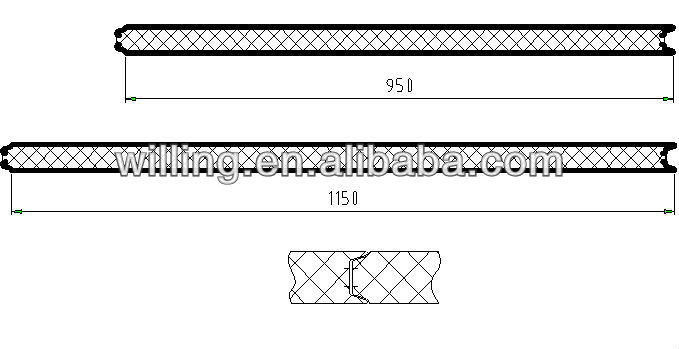

(see profile drawing) |

3 |

thickness |

(see profile drawing) |

raw material specification | ||

1 |

coil thickness |

0.4~0.6 mm (steel be flat without ups and downs,deformation and bending) |

2 |

coil stress |

≤235MPa |

3 |

coil max width |

1200 mm (tolerance±2mm) |

4 |

coil max weight |

5t |

5 |

coil ID |

500 and 600 mm |

6 |

coil OD |

1000 mm |

7 |

EPS material |

density is≥18kg/m3,unstraight of each side ≤mm/m,,curve ≤mm/m,surface be even,ineveness smaller than 1.mm/m,EPS material single piece length more than ≥3m. |

8 |

Rockwool material |

length more than 100mm,vertical lined,density ≥100kg/m3 ,single piece length more than ≥3m |

9 |

Material suitable shape |

see profile drawing.(prepared by customer and according to the ) |

10 |

Material suitable width |

minimum shall be 1/2mm of the finished panel width. |

Machine line specification | ||

1 |

Work line speed |

1000-3000mm/min (frequency speed adjustment).attention:depend on glue brand, temperature and proficiency of operators. |

2 |

Machine length |

about 40 m |

3 |

Working height |

1050 mm(panel output height) |

4 |

Laminating effective length |

7.5 m |

5 |

Control way |

adopt industrial computer PLC |

6 |

Total power |

about 40 kw |

7 |

power |

380V/3phase/50 Hz |

8 |

control voltage |

24 V/110 V/220 V |

9 |

pneumatic |

0.7 Mpa (self prepared by factory) |

10 |

best working temperature |

around 25°C |

2. Composante

|

1) roll foming machine | |

A) |

Hydraulic uncoiler |

B) |

Guide device |

C) |

Filming system |

D) |

Flat sheet slitting system |

E) |

Roll forming system |

F) |

Panel support frame |

G) |

Assistant forming system |

2) Laminating body | |

A) |

Guiding device |

B) |

Inside material feeding device |

C) |

Laminating |

D) |

Film covering device |

E) |

Cutting device |

F) |

Glue supplying system |

G) |

Gelatinizing device |

H) |

Core material groove making system |

I) |

Dusting device |

J) |

Electrical controller |

Informations sur la société

Informations sur la société

Groupes de Produits : Machine à former les petits pains EPS

Premium Related Products